eManager Integration

This documentation provides an overview of what eManager is capable of and serves as a reference during initial installation and subsequent configuration changes.

Before implementing any integration to eManager, contact Element Logic's Design and Consulting department to set up a workshop to review and approve the integration specification. Once in production, please contact Element Logic Support before making any configuration changes, as you may unintentionally reduce the performance of your AutoStore installation. Changes in the integration should always be made in a test environment before being applied to the production environment.

Time spent by Element Logic correcting issues caused by configuration changes that were made without first contacting Element Logic is not covered by the SLA and will be billed separately.

If you are ever in need of additional help, please contact Element Logic Support.

Introduction to eManager

eManager is Element Logic's in-house developed AutoStore management software. It enables you to:

- Move products into and out of AutoStore

- Track inventory in AutoStore

- Locate products in AutoStore

- Handle returned goods

- Optimize inbound and outbound processes

- Integrate ERP/ WMS and other supply chain systems with AutoStore

- Predict when AutoStore will need service and maintenance

How it works

- AutoStore-optimized user interface

- Built-in AutoStore operator assistance

- Product location and inventory control

- Operational dashboard and service portal with advanced service and maintenance diagnostics

- Management of AutoStore warehouse processes, including optimized inbound and outbound processes designed specifically for AutoStore

- Intelligent algorithms for AutoStore wave picking, batch picking, handling of returned and high frequency products, and more

- Integration with ERP / WMS, Robotic Piece-picking Solution by Element Logic, and a variety of warehouse supply-chain systems

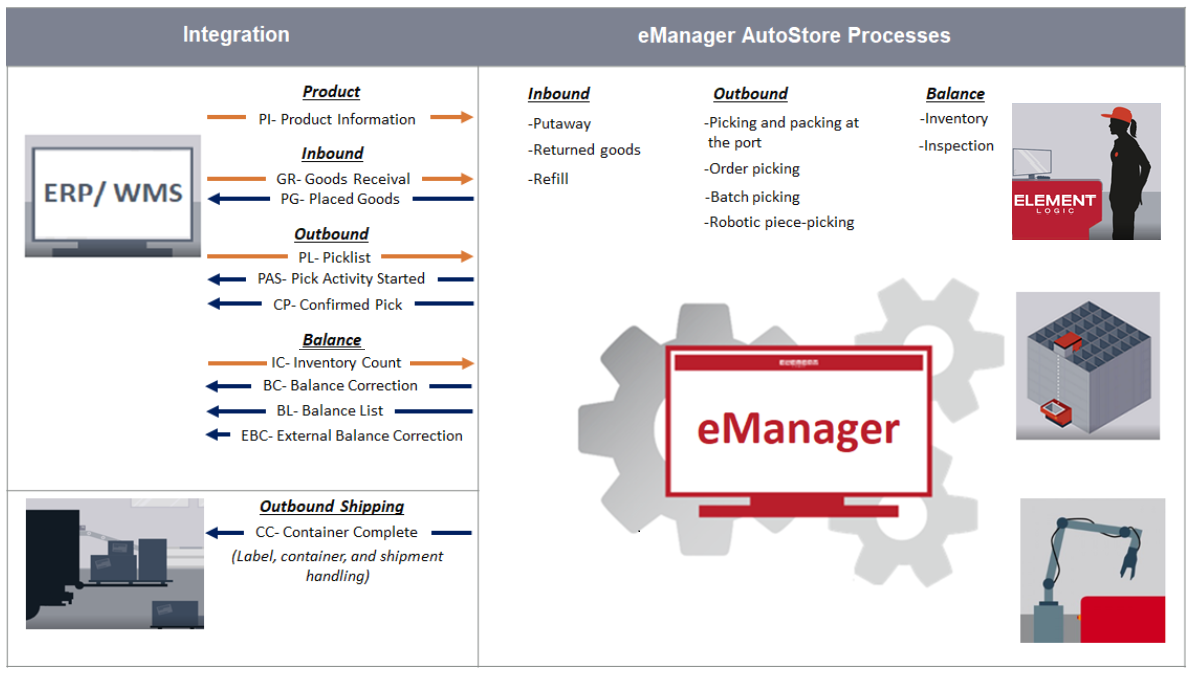

Overview of eManager processes

Product

Inbound

Outbound

Balance

Relationship to other systems

WMS / ERP

eManager must be connected to a system that provides details of goods that are inbound to, or outbound from, AutoStore. Because eManager only controls inventory stored in AutoStore, a warehouse that has inventory stored outside AutoStore needs a separate system to control the rest of the warehouse. The system eManager is integrated with does not need to track what is stored in any particular AutoStore bin, it is sufficient to know what inventory is stored in AutoStore as a whole.

Because eManager only manages inventory stored in AutoStore, inventory stored outside AutoStore needs a separate management system. Transferring this inventory to/ from AutoStore is done by normal putaway and order picking/ batch picking.

TMS

If orders are packed directly at the AutoStore ports, it may be necessary to print labels from a TMS system at each port. There are two ways of handling this:

WMS/ ERP- Trigger printing by sending a message from eManager to the WMS/ERP system, which then sends the message to the TMS system.

eManager- Integrate eManager directly with the TMS system to significantly reduce the time operators spend waiting for labels. This means more data, including personal data about the recipient, must be sent to eManager. However, this data is passed directly to the TMS system and is not used by eManager.